Technology

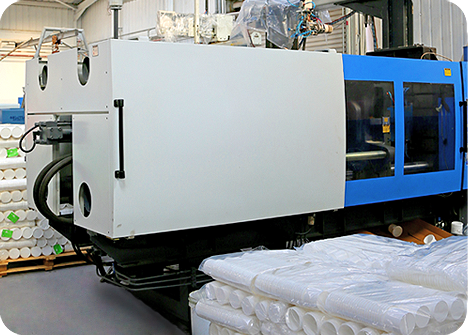

Horizon emphasizes on introducing latest machinery and technology in our field.

Our Injection and Blow Moulding machinery are the newest models with high efficiency and energy saving machines combined with high quality molds.

Our offset printing foils can print up to six colors with high definition.

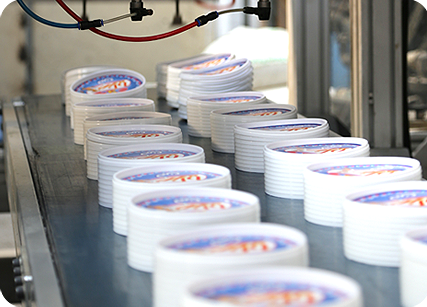

IN-MOULD.LABELING

(Decorating Technology)

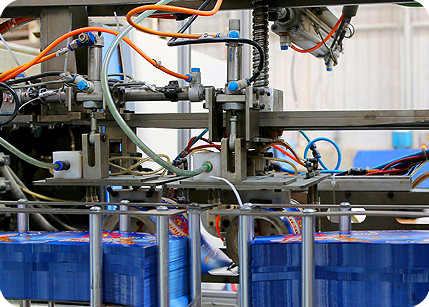

Since three years Horizon introduced In-Mould Labeling automation systems to deal with in mould labeling decoration. In-Mould Labeling is an extremely Accurate Process and requires the intervention of experienced craftsmen

First step a pre-printed Polypropylene label is placed in the mould using Robots just before the mould is closed during the injection moulding process. When the mould is injected with molten PP the label literally fuses with the packaging material, the end result is a printed packaging ready to be delivered .Everything happens in one step

There are many advantages to this process

* Best printing quality and 3D decorating capability available.

* Better appearance, finishing and quality

* Hygienic and strong against scratch, humidity, heat and very low temperature

* Cost effective due to the automation equipment

* Exceeds FDA and child safety requirements

* Environmentally friendly as the label and package consists of the same material and can therefore be fully recycled

With expansion in our warehouses we are able to reduce delivery time to a minimum and as such helping our clients to decrease their inventory of plastic containers.